In today's production landscape, the allure of the flawlessly concluded merchandise usually overshadows a essential consideration: the wellbeing and basic safety of your men and women responsible for bringing that product or service to daily life. the whole world of electroless copper plating, essential for plenty of industries from electronics to automotive, is not any exception. even though the method delivers the desired conductivity and corrosion resistance, What's more, it offers A selection of probable hazards to staff who take care of the specialised plating chemicals concerned. this short article delves into the usually-ignored location of worker safety in copper plating, specializing in the dangers connected to substances like MPS Sodium (3-Mercaptopropanesulphonate) and outlining sensible techniques to mitigate these dangers and make certain a healthier, far more sustainable Functioning setting. For businesses searching for a dependable electroless copper plating maker, comprehension these protection factors is paramount.

Table of contents:

knowledge the Chemical Landscape - MPS Sodium and its Houses

Exposure Pathways - How Workers Come into Get hold of

the strength of individual Protective devices (PPE)

Engineering Controls - Building a Safer natural environment

Emergency Response and Preparedness - arranging for that Unexpected

very long-expression health and fitness checking - Addressing Persistent publicity

Streamlining Processes with Automation - cutting down Human Error

knowing the Chemical Landscape - MPS Sodium and its Qualities

3-Mercaptopropanesulphonate (MPS Sodium), frequently applied like a brightener and accelerator in copper plating baths, is a powerful chemical compound that offers a unique list of troubles. To fully tackle employee protection, It can be very important to understand the inherent Houses of this substance:

discomfort Potential: MPS Sodium, in its concentrated sort, might be an irritant for the pores and skin, eyes, and respiratory program. The presence of volatile sulfur-made up of compounds, particularly thiol teams (-SH), can launch noticeable odors that may cause discomfort or respiratory discomfort in delicate folks.

Corrosivity problems: based on the formulation as well as pH on the plating bath, MPS Sodium-containing options may exhibit corrosive Attributes. This is especially pertinent in electroplating processes that include acidic or alkaline electrolytes, which can exacerbate the corrosive effects.

possible for Toxic Impurities: The manufacturing means of MPS Sodium can in some cases bring on the presence of trace impurities, for instance unreacted sulfides or hefty metals. even though these impurities are generally current in modest quantities, their long-expression wellness effects need to be viewed as.

Exposure Pathways - How staff Come into Contact

figuring out likely publicity pathways is the next critical move in employing successful protection protocols. personnel is often subjected to MPS Sodium together with other plating chemical substances via quite a few routes:

Inhalation: Vapors or aerosols produced throughout the plating process, especially when the plating bathtub is heated, might be inhaled. The volatility of specified parts within the plating Resolution, like natural and organic amines or residual solvents, can contribute to airborne contamination.

Skin Make contact with: immediate pores and skin contact with concentrated MPS Sodium solutions, plating baths, or contaminated surfaces is a major risk. Even transient or seemingly insignificant Make contact with can lead to irritation, dermatitis, or chemical burns, depending on the concentration and duration of exposure.

Ingestion: Although much less prevalent, accidental ingestion can manifest as a result of poor hygiene tactics inside the place of work, like having or drinking in parts in which chemicals are managed.

Eye Make contact with: Splashes or accidental connection with plating answers might cause extreme eye discomfort or even permanent damage if not addressed immediately.

The Power of individual Protective products (PPE)

individual Protective Equipment (PPE) forms the first line of protection against chemical publicity. selecting the suitable PPE, and making certain its suitable use, is important.

Hand Protection: deciding upon the appropriate glove product is essential. common latex or nitrile gloves may not deliver suitable defense versus MPS Sodium as well as other chemical substances used in electroplating. Gloves product of butyl rubber, neoprene, or other chemically resistant resources will often be necessary. The glove's thickness and cuff duration also needs to be regarded as to offer enough barrier defense.

Respiratory safety: depending upon the focus of airborne contaminants, respiratory protection could possibly be expected. This could range from uncomplicated dust masks to respirators Outfitted with suitable cartridges or filters made to take away natural vapors, acid gases, or particulates.

Eye and experience Protection: protection Eyeglasses with side shields or, better still, an entire face defend must be worn to guard versus splashes or accidental contact with plating answers.

protecting clothes: Chemical-resistant aprons or coveralls should be worn to guard the pores and skin from connection with substances.

Engineering Controls - developing a plating chemicals manufacturer Safer Environment

even though PPE is vital, engineering controls present you with a more sustainable and efficient method of minimizing employee exposure. These controls give attention to modifying the get the job done environment to reduce or eradicate hazards.

Ventilation units: nearby exhaust air flow (LEV) methods are essential in electroplating services to seize and take away airborne contaminants at their source. These methods must be made to seize vapors, fumes, and aerosols generated in the course of the plating approach. normal maintenance and checking of ventilation devices are critical to be sure their effectiveness.

Enclosure and Isolation: Enclosing or isolating plating functions can avert the distribute of contaminants and lower the risk of exposure. this will require working with enclosed plating tanks or automated systems that minimize the necessity for manual dealing with of chemicals.

Spill Containment: applying spill containment measures, for example setting up drip trays, bunds, or spill containment limitations, can protect against spills from spreading and contaminating the function environment.

automatic Systems: employing automatic techniques for chemical managing, for example automatic dosing systems or robotic arms, can lessen the necessity for handbook intervention and decrease the potential risk of exposure.

unexpected emergency reaction and Preparedness - setting up for the surprising

Despite the ideal preventive actions, incidents can continue to take place. possessing a properly-outlined crisis reaction approach set up is vital for minimizing the influence of incidents.

Emergency treatments: obvious and concise emergency procedures needs to be developed and communicated to all personnel. These strategies must outline the measures to take in the celebration of a spill, publicity, or other unexpected emergency.

to start with support: satisfactory to start with aid amenities, which include eyewash stations and crisis showers, needs to be readily available during the place of work. personnel needs to be experienced in standard to start with support techniques, together with how to reply to chemical exposures.

Spill Response Kits: Spill response kits that contains appropriate absorbents, neutralizers, and personal protective machines really should be available in locations exactly where substances are managed.

standard Drills: Conducting standard crisis drills may help to make certain that staff are familiar with emergency strategies and might respond successfully from the function of an incident.

very long-time period overall health Monitoring - Addressing Continual publicity

The probable extensive-term wellness outcomes of publicity to plating chemical substances, even at very low concentrations, really should not be overlooked.

Exposure checking: typical checking of worker publicity concentrations to plating chemical substances can help to identify opportunity health and fitness risks and be certain that Regulate measures are effective.

wellness Surveillance: employing a wellness surveillance method, such as periodic clinical examinations and Organic checking, may help to detect early signs of health issues relevant to chemical publicity.

document Keeping: sustaining precise records of employee exposure degrees, overall health surveillance data, and any incidents or accidents may help to establish tendencies and designs and to evaluate the success of Regulate measures.

Worker education and learning: Providing staff with comprehensive details about the probable well being consequences of publicity to plating substances and the significance of subsequent security treatments will help to advertise a tradition of protection and stop lengthy-phrase health conditions.

Streamlining Processes with Automation - decreasing Human Error

reducing human error is a critical facet of enhancing safety. automatic processes give considerable strengths During this region.

Pre-blended alternatives: utilizing pre-combined chemical options can reduce the need for guide mixing and reduce the chance of glitches in focus.

automatic Dosing programs: automatic dosing techniques can make sure chemical compounds are included to plating baths in the right proportions and at the appropriate moments, reducing the potential risk of chemical imbalances or dangerous reactions.

Robotic managing: working with robotic arms to manage chemicals can lessen the require for guide handling and lower the chance of publicity.

Closed-Loop Manage: Implementing shut-loop Regulate methods that keep track of and modify plating bathtub parameters might help to maintain best plating conditions and stop the Construct-up of harmful substances.

Section eight: The function of Suppliers in Promoting basic safety

Chemical suppliers Engage in a vital part in advertising and marketing employee basic safety by delivering extensive details about the hazards connected to their merchandise and presenting direction on Risk-free handling techniques.

Safety info Sheets (SDS): delivering precise and up-to-day Safety info Sheets (SDS) which include comprehensive details about the hazards, handling precautions, and emergency methods for each chemical products.

specialized assistance: giving specialized support to buyers on Secure managing procedures, including advice on the selection and use of non-public protecting tools, air flow units, as well as other control actions.

instruction plans: building and delivering coaching applications for workers within the Safe and sound handling of chemicals, including arms-on demonstrations and practical exercises.

product or service Stewardship: Implementing merchandise stewardship applications that promote the accountable management of chemical substances during their lifecycle, from manufacturing to disposal.

Prioritizing employee health and fitness and safety in electroless copper plating is just not simply a issue of compliance; It is an investment in the extensive-expression sustainability and results of any Group. By knowledge the inherent dangers related to substances like MPS Sodium, utilizing strong Regulate measures, and fostering a society of protection, businesses can make a healthier and more effective work ecosystem.whilst there are lots of plating chemicals producer out there, some, like Fengfan Trade, are devoted to giving not only large-top quality chemicals but also extensive guidance and sources that will help prospects make sure the Risk-free and dependable use in their solutions. deciding on a associate that prioritizes both of those overall performance and safety is a vital phase in direction of building a brighter, more healthy upcoming to the plating marketplace.

Scott Baio Then & Now!

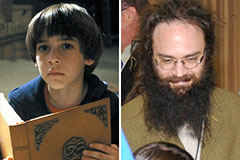

Scott Baio Then & Now! Barret Oliver Then & Now!

Barret Oliver Then & Now! Shane West Then & Now!

Shane West Then & Now! Michelle Trachtenberg Then & Now!

Michelle Trachtenberg Then & Now! Lacey Chabert Then & Now!

Lacey Chabert Then & Now!